flagpoles

Durmax - first-class flagpoles and flags

www.durmax.eu

Patrinus Digital is the exclusive distributor of Durmax flagpoles.

First-class Durmax flagpoles, made of fibreglass-reinforced polyester, are a combination of advanced Swedish technology and decades of experience of the world's best flagpole manufacturers.

Their main features are…

Elegant. Light. Flexible. No grounding is required. Rust resistant. Low or no maintenance. Durable. Long-lasting.

For outdoor events, where you don't want to miss the opportunity to be recognizable and noticed from afar, you will need portable and practical telescopic flagpoles. Durmax Escalion, adjustable in height from 1.8 to 5.5 m, is undoubtedly the best choice and will serve you faithfully for years.

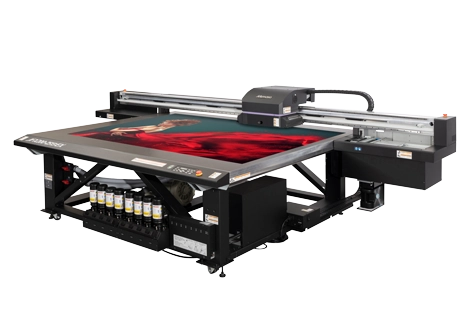

In addition to Durmax polyester flagpoles and Durmax Escalion telescopic flagpoles, as part of the Durmax Companion production program, we also offer the production of high-quality flags of various types, materials, dimensions and purposes, digitally printed on top industrial machines, with careful and precise final assembly.

services

services